Compressible abrasives for a perfect finish

Finding technically skilled employees is no easy task. Especially for grinding and sanding, still largely manual skills, which only really take time and experience to master. This is why manufacturers have developed what are known as compressible abrasives. These sanding materials are inherently "forgiving," allowing even less experienced sanders and grinders to achieve a beautiful finish, without mistakes in the workpiece.

Workpieces must meet increasingly stringent requirements, both aesthetically and technically and functionally. But just today, the scarcity of specialized sanders is making itself felt harder than ever. Classic sanding materials, however, allow little margin for error. In order to achieve a beautiful finish, the operator will have to have a firm grasp of sanding or grinding. If one sands too quickly, irreparable damage may occur to the workpiece. If one sands too slowly, there will be no return on investment. For manufacturers of abrasives, this was the signal to look for a new type of abrasive that was more forgiving.

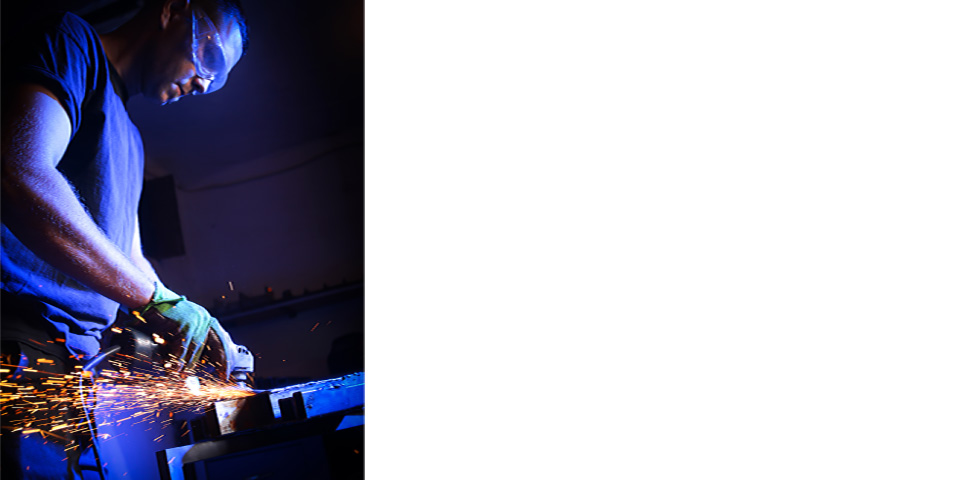

Still, time is saved for most metal companies precisely because compressible abrasives greatly reduce the risk of errors. (Image: Csaba Toth)

Accommodate aggressive sanding movements for uniform finish

The result of these investments and developments are the so-called compressible or 3D sanding materials. These have been around for decades, but they have found a new application as compressed plates (unitized abrasives) with a controlled density, opening the door to new applications. While compressible ones use the same abrasive grains as the classic abrasives (aluminum oxide, zirconium, ceramic, etc.), the difference lies in the compressible 3D web in which they are impregnated. This allows them to absorb the most aggressive abrasive movements for a uniform finish. Where the grains would otherwise penetrate deep into the workpiece, they now largely disappear into the web, taking some of the edge off. No more (deep) scratches! A second advantage is the lower heat development, so workpieces are less likely to deform or discolor. On the other hand, there will be less material taken off. Still, for most metal companies there is a time gain, precisely because compressible abrasives greatly reduce the risk of errors.

Different operations in a movement

The developments did not stop there. By combining several compressible abrasives, it becomes possible to perform several operations at once. In one motion, the operator then works away the weld, applies a brush texture and removes weld discoloration on the outside of the weld. This is in line with the prevailing trend in sanding and polishing where the classic, rigid step-by-step plan that for years dictated how to work is being abandoned. Now, instead, people want to try to get the sanding job done in as few moves as possible. The gain is in no longer having to change sanding discs and the time this saves. In addition, the advent of sanders with adjustable speed also made a difference. The operator can start determining that according to the sanding material, diameter and workpiece. So sanding and grinding remains a matter of knowing the right parameters. Now, it remains a stile, but experience or training will make less of a difference in execution for a perfect finish. Possible applications for compressible materials include removing weld discolorations, breaking corners, deburring and rounding, correcting sanding errors, removing scratches, removing milling lines, removing paints and coatings, pre-polishing, improving surface roughness ...