Randomly choosing a gripper is not enough

Although advances have been made in the design and operation of electric grippers, pneumatic grippers have been the standard for many years and will remain so for the foreseeable future. In today's automated production, more than 95% of grippers are pneumatically driven. Under the brand name RobohandTM, Destaco develops and manufactures innovative pneumatic and electric grippers, including the successful G110 gripper series. Choosing the right gripper depends on many factors. It is not enough to randomly take a gripper from the rack or order it from the catalog.

When designing pick-and-place automation systems for use in a wide variety of applications, engineers often pay insufficient attention to the choice of the most appropriate gripper. "However, the gripper is an important part of the system and there are also many different gripper styles available," says Fred Voogel, general manager of Destaco Benelux. "When choosing the gripper, you have to consider many factors, including the effect of dirt, grit, oil, grease, cutting fluid, temperature fluctuations, cleanliness and the level of human interaction on the operation of an automation system. In addition, gripper design and construction as well as the specific control environment also play a role."

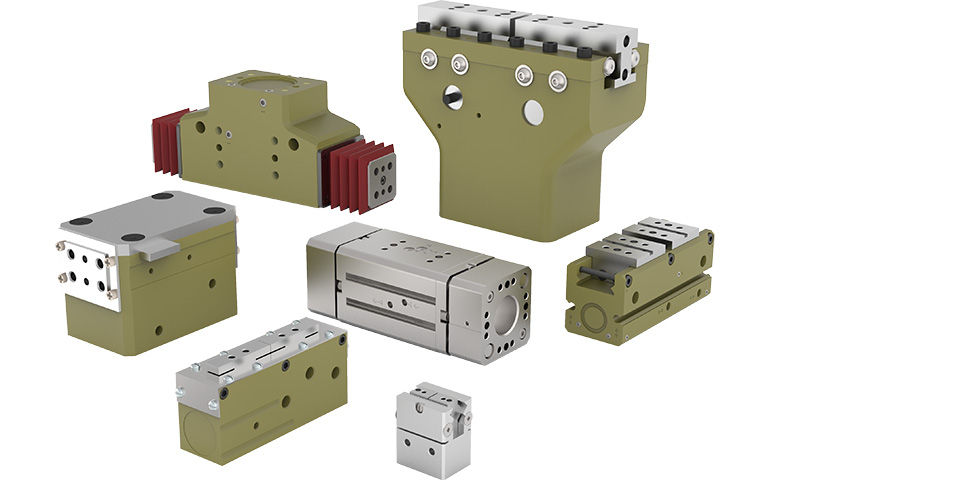

Destaco's product family consists of several leading brands, including the RobohandTM grippers.

Gripper design and control environment

The design and construction of a gripper affect its performance in a given work environment. Every gripper consists of three basic elements: the body with the parts for force transmission, the jaws and the fingers. The gripper manufacturer designs and builds the body and jaws, while the machine builder or end user provides the custom fingers to grip or encapsulate the given part. Finger size, gripping force, stroke, activation time and accuracy are some aspects, which one must consider when selecting a gripper. Manufacturers also provide those specifications with each gripper model. "Specific control environments also play an important role in determining the type of gripper design," Voogel adds. "For example, the jaw support mechanism (bearing type) and internal design or the method of force transmission from piston to jaws can have an impact. Grippers may be the same size and function, yet completely different designs, making some models better than others for a given control environment."

Destaco gives advice

Those looking for technical support in choosing the right gripper can always turn to Destaco, leading global supplier of solutions for precision motion, positioning and control in industrial automation. The product family consists of several leading brands, including Destaco itself (hand and power clamps and end-effectors), CAMCOTM and FergusonTM (indexers), CRLTM (manipulators and transfer gates) and RobohandTM (grippers). "The performance of an automated manufacturing system is only as strong and reliable as the performance of their weakest link. To ensure, that the gripper is not the weakest element, one must pay attention to the control environment and the appropriate gripper, specified based on the design and available options. This may be a standard solution, but an application may just as easily require a custom gripper," Voogel concludes. "If designers and engineers don't do this at the design stage, it can have a negative impact on the operation of the automation system and they still end up having to find the right gripper."