Flexible punching machine helps lay foundation for revolution in steel structures

An approachable steel building system for homes. That's what Iwo Swenters had in mind when developing Skellet. The patented design provides the same torsional rigidity but less weight, opening the way to cheaper and more sustainable construction. Step by step, production will be taken into our own hands in the production hall in Genk. TRUMPF's TruPunch 1000 already proved to be the first right step in the right direction.

The linear magazine is more than sufficient for Skellet. A change only needs to be made when plates of a different thickness are put on the machine.

Skellet revolves entirely around the product of the same name. A unique, patented profile for steel construction that, like a mecanosystem, makes the most complex constructions possible. Managing director Ivo Swenters: "The current steel and aluminum profiles are excellent for industrial construction, but are inadequate for housing. The connecting plates are always in the way. That is why we developed a unique shape for a closed box section, where the four corners were set back. Thanks to this shape, the fact that there is no need for welding and the flexibility of the system that allows us to stop material where needed and omit it where not needed, we can achieve a weight saving of 50% compared to conventional steel building structures. A huge gain in cost for the company and for the environment. Moreover, the profiles 100% are reusable, opening the way to circular construction." There are also advantages for designers and structural engineers. The dimensional stability of the system (on a 25 mm matrix) greatly reduces the error burden, while only a limited investment is required (some hand tools and a sawing machine) to get started.

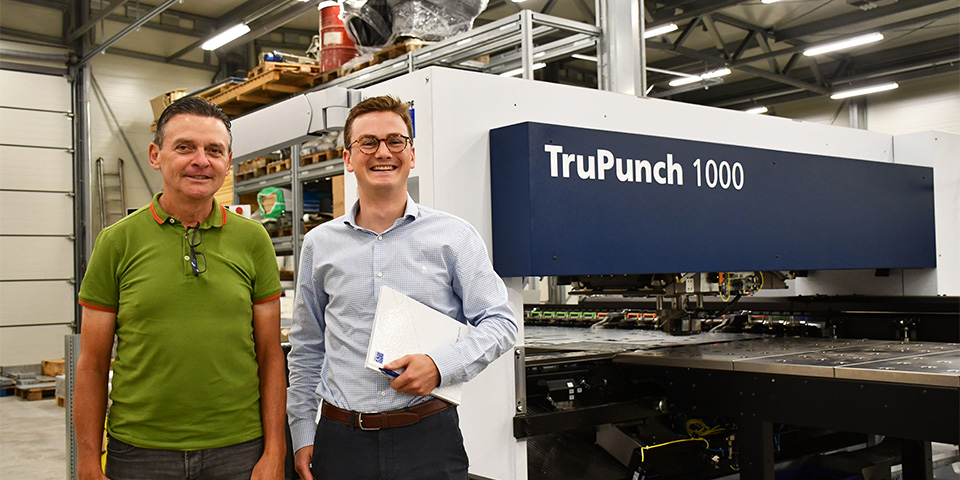

Ivo Swenters (Skellet) and Francis Sercu (V.A.C. MACHINES). "The TruPunch 1000 is a particularly flexible machine that allows us to make anything we need."

First sheet metal working machine

Swenters wants to revolutionize the construction world with Skellet. This will be done from the headquarters in Genk where an investment of about 10 million euros in production capacity will soon follow. "For now, the production of the profiles is still done by a supplier in Spain. What we do already carry out in-house is the production of the standard and customized connectors. Working with a supplier gave us too little flexibility to have the right pieces quickly. After all, as soon as we deviate from the 25 mm grid, for example to work at an angle, the connectors are always the right size. The rest we can solve with a wide range of standard pieces." For these connectors, a brand new TruPunch 1000 has been adorning the production hall since April. For Swenters, the machine could only come from TRUMPF. "They set the standard in sheet metal processing and also have a unique concept in punching. Everywhere we went to turn our lights on in the area, there were TRUMPF machines working."

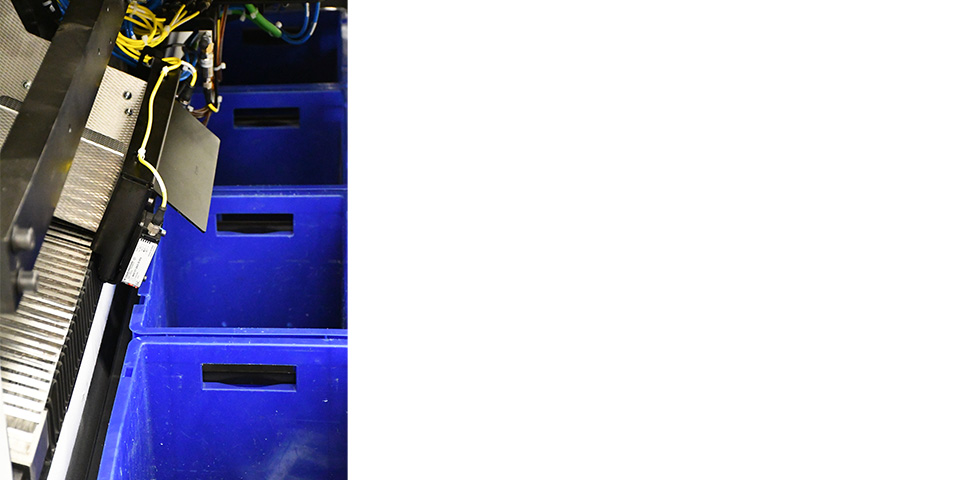

Either sorting system on the TruPunch 1000.

Punching: faster, cheaper and better

At the supplier, these pieces were laser cut. However, supplier V.A.C. MACHINES from Bruges quickly showed that a punching machine would be the better investment in this case. Swenters: "The fact that we work with galvanized materials means that with laser there is more risk of rusting. With the punch this is greatly reduced. A punching machine with its additional tools also gives us enormous possibilities for additional operations such as wire tapping, making reinforcement ribs, forming ... with which we can further develop and grow in the future." A comprehensive study (speed, productivity, automation options) of the different models then pointed to the updated TruPunch 1000 as the ideal machine. "Especially because it allows fully automatic discharge and sorting of pieces. A huge advantage, since we fill our nestings of custom pieces with the standard connectors," Swenters adds. The TruPunch 1000 features two sorting options: a smaller discharge system (180 x 180 mm) for sorting out into four trays and a larger full-width flap for the larger pieces.

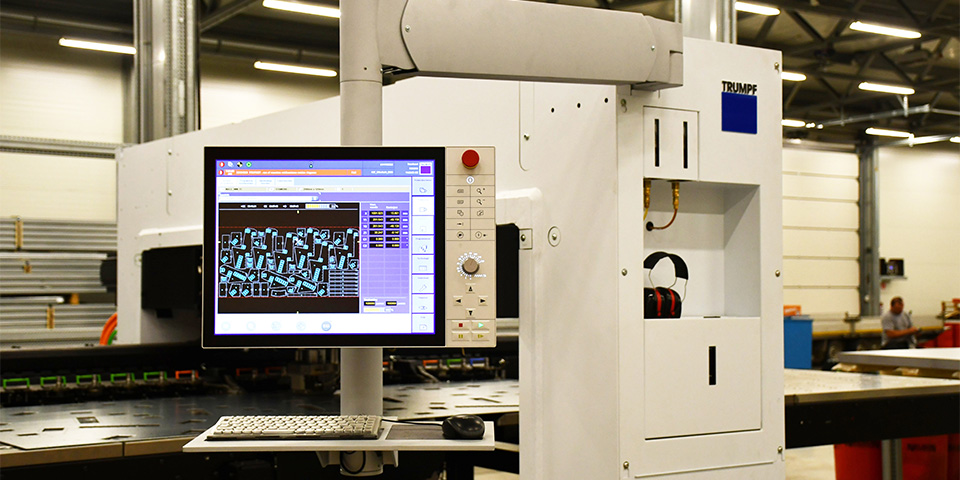

The operators were particularly quick to get away with operating the machine.

Perfect support

For Skellet, it is the first introduction to sheet metal working technology. It is therefore a particular learning path that must be followed to fully master the punching process. Two employees are in charge of the programs and two operators at the machine then turn it into a flawlessly finished product. Swenters: "V.A.C. MACHINES has supported us perfectly in this. First with the training in Bruges, but later also when the machine was here to set all the parameters correctly. Meanwhile, everything runs flawlessly. The result for us is a particularly flexible machine with which we can make everything we need."