How to arrive at the right lathe?

Turning is one of the oldest machining processes in the world, dating back as far as Egyptian times. A rich history, then, but that is by no means to say that developments in turning have already dried up. Modern turning centers and lathes are a strong example of sophisticated technology. But there are some knots to be cut to arrive at the right machine for your process.

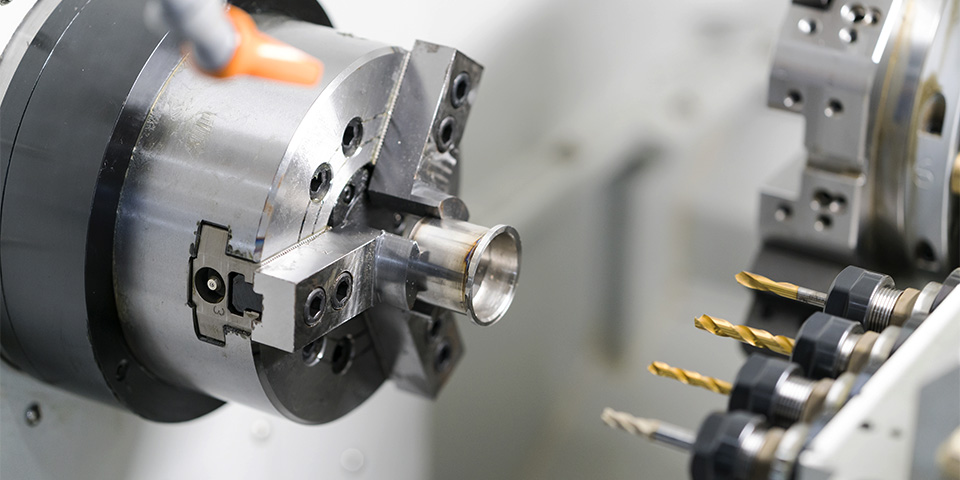

A lathe or a turning center? In theory, there is no difference. In practice, the distinction is made in the addition of additional operations. If only turning is done with the machine then we speak of a lathe. If there is also milling, drilling or tapping involved or a subspindle for additional operations then we are dealing with a turning center. They offer more than just turning and are actually a further development of the CNC lathe.

In gang tooling, the tools are in a row in the lathe. This method lends itself more to machining small pieces.

Horizontal or vertical configuration?

CNC turning centers exist in horizontal and vertical versions. In addition, there are those that reverse vertical turning by changing the position of the spindle and chuck. Each type features the same components. The difference is purely in the orientation. But what should you keep in mind to choose the right configuration for your application? The advantage of horizontal turning is that gravity pulls chips away from the workpiece. They fall down onto a chip conveyor or hopper. On vertical lathes, gravity will help lock the workpiece into its holder. Chips can then cause problems, especially if the pieces are concave. So a very efficient protection must be present to prevent the chips from damaging the workpiece. Horizontal lathes are more flexible, as they have longer bed lengths relative to their spindle size. But when short large-diameter pieces need to be machined, especially if they are heavy pieces, a vertical lathe will produce better results. Size is the biggest differentiating factor between the two configurations. In addition, the degree of automation will be a determining factor. For horizontal turning, it will be easiest. With vertical, you do have the advantage that the robot does not have to push the piece into the seat thanks to gravity. Here also lies the added value of reverse vertical turning. The spindle can then pick up the piece, so no robot is needed for handling.

Between lathes and turning centers, the difference is mainly in the fixtures. In many cases, turning centers require a fixture tailored to the workpiece.

Turret tooling or corridor tooling?

How the tools should be applied often provides much food for discussion. There are two systems. In turret tooling, the cutting tools are mounted in a rotating, indexable tool holder. In gang tooling, they are in a row in the lathe, similar to the table on a milling machine. The latter method lends itself more to machining small pieces that require only a limited number of tools. Indeed, cycle time can be minimized because no index time needs to be counted for the turret. Tool changes also take little time. Ideal for large series. With a turret, the added value lies in the larger working range and less interference from tool to tool.

It also adds flexibility because more tools can be kept ready, which means, for example, not having to change for the next piece. In general, a turret works better for larger pieces. If you have a wide range of pieces and are looking for flexibility, turret will be the best option.

Workpiece size is the biggest differentiating factor between the two configurations.

Powered tools?

Lathes and centers can also be equipped with powered tools. These then receive their power from an independent electric motor. There is then no belt transmission involved; the tool functions as an integral spindle. Most users do not realize the potential benefits until they use powered tools. As runs become smaller and machine capacities increase, powered tools will continue their advance. After all, they reduce a lot of the manual work that conventional CNC turning involves.

Automation or not?

Automation has become increasingly hard to imagine on the shop floor since the dawn of Industry 4.0. CNC lathes are no exception. The configuration of the lathe will have an impact on what that automation solution looks like, though. Horizontal lathes are usually loaded by an operator. This is where a robot or a gantry crane comes into play. A good maxim is to keep the robot 80% of the time working. Therefore, it often operates two machines. Between lathes and turning centers, the difference is mainly in the fixturing. In many cases, turning centers require a fixture tailored to the workpiece. With a lathe, a chuck with three jaws usually suffices. Here there is very great flexibility in workpieces.

Horizontal lathes are usually loaded by an operator. A robot or gantry crane then comes into play there if one wants to automate.

Common errors in CNC turning?

Maximizing efficiency is paramount on the production floor. That goes hand in hand with minimizing errors. Operators often want to push the feed and speed. For example, they do 20% more than what is recommended. That can be done, but that can also lead to a lot of damage. So that is when it is best to keep an eye on things. However, by slowing down a bit, one can greatly reduce the risk of tool breakage. The cycle time may seem lower, but at the end of the month the throughput will be higher. In addition, of course, training is important. These are high-tech machines. So give personnel (operators, work planner, programmer ...) all the skills to get the most out of that machine.