Smart multitasking machines reduce cost per product

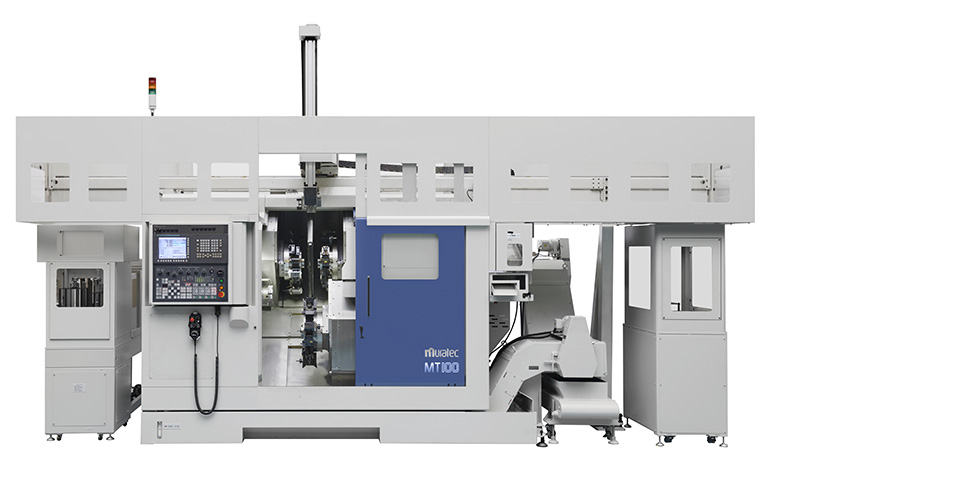

Smart manufacturing is about the extensive digitization and automation of production machines. This development has also been taking hold in machining for years. Because by producing smartly, the cost price per product in particular goes down and more continuity is created. In the market, therefore, there is much to do with robotization and other forms of automation. But Japan's Muratec has been a supplier of multitasking machines that produce smart for decades. In addition, they are constantly developing new systems to make a production machine produce even smarter.

Muratec Machine Tools is part of the Japanese company Murata Machinery. Decades ago, a lathe with automated loading and unloading was developed by this company. The gantry loaders and unloaders have been unique for years. Not only in application, but certainly also in speed. By using, for example, a second spindle and/or three tool turrets, the turning process is certainly just as advanced. The programming of these complex machines has long proven itself. By using multiple programs in parallel, the machine is able to "multitask.

Muratec on the Belgian market

Muratec machines have been used in the Belgian manufacturing industry for a long period of time. Bendertechniek Bvba acquired the dealership in 2016 and thus assumed the sales and service activities in Belgium. A nice example of smart production with Muratec machines, is the new production line at an automotive manufacturer. A number of Muratec machines with double front spindle are used here. The machines together with other machines, form a production line in which products are produced in a number of steps. The turning machines work together with a roller and an oven, among others. The infeed and outfeed and the mutual distribution, are done with Muratec's automation system in cooperation with the other robots. Where previously many human actions had to be performed, there is now an independently operating production line.

Novelties

As a machine manufacturer, Muratec has mastered the automation of a multitasking machining system for many years. Therefore, in recent years they have put a lot of energy into developing extensions that are desired in a production line. Thus the Muratec machines can be expanded with the following devices (in addition to the already known loading and unloading systems):

- De-stackers for buffer stock material feeding

- Automatic measuring station for

intermediate measurements - Wash station to clean products

- Buffer positions, to buffer products between two in-line machines

- Stackers for efficient collection of finished product

These extensions are modularly built so that a machine can be assembled with any of the aforementioned modules. In addition to these systems, a Muratec machine can easily be connected to a bar feeding system, for example. This also eliminates the step of sawing the material.

Smart manufacturing

The result is a production machine for metal or plastic parts, which produces from rod material to finished product. The use of different modules thus allows each user to put together a machine for himself. The biggest advantage of this is that the various modules work seamlessly with each other. This is because the hardware and software were developed by the same people. When a turning machine is expanded with external systems, the installation time is many times longer. Moreover, it makes a system much more susceptible to malfunctions. By choosing one machine with extensions from the same manufacturer, this is avoided.